05.07.2021

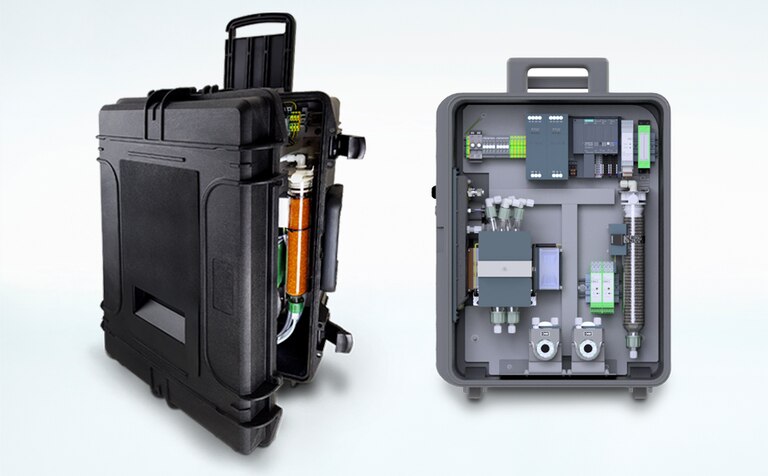

Portable Sampling System PSS-STS

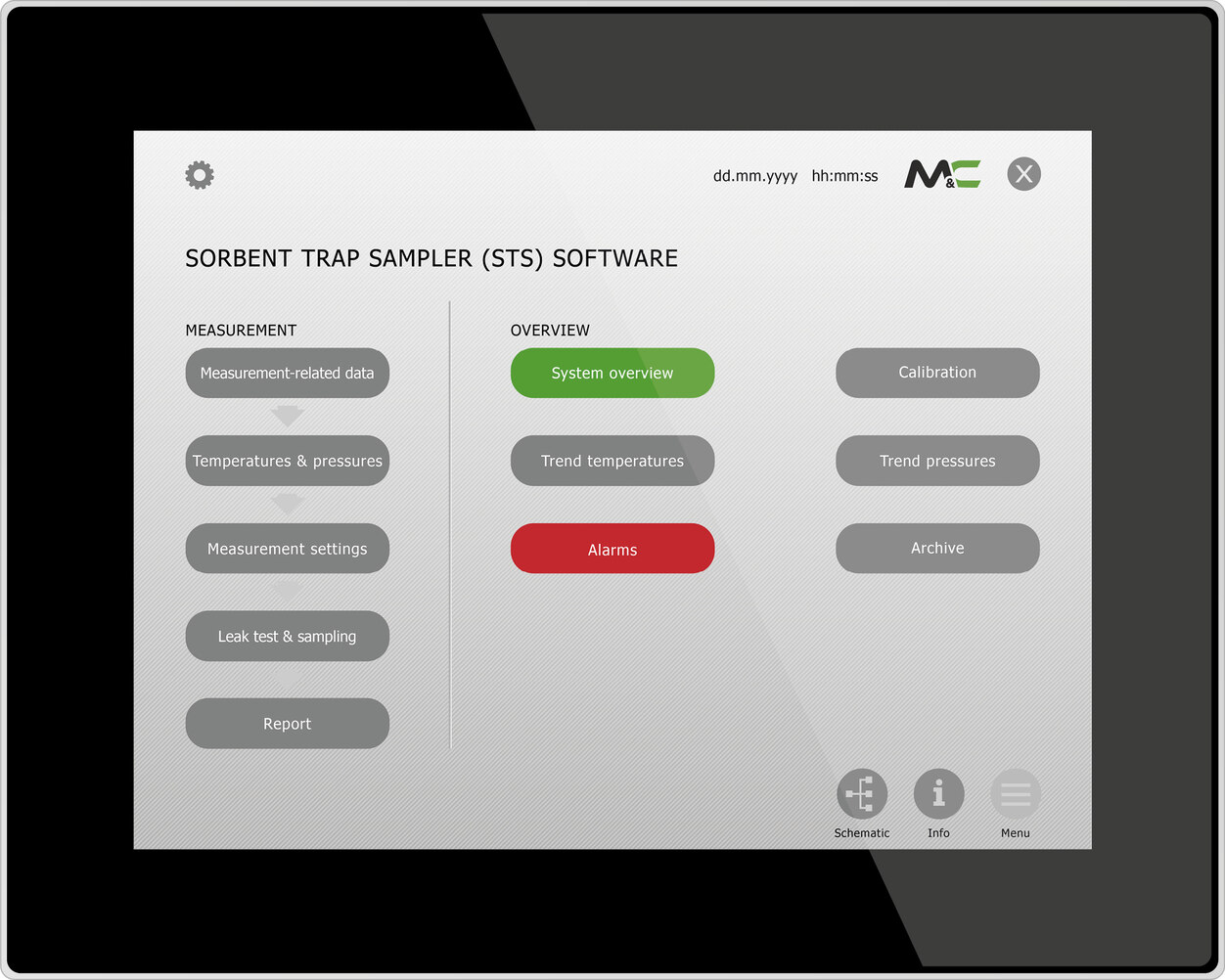

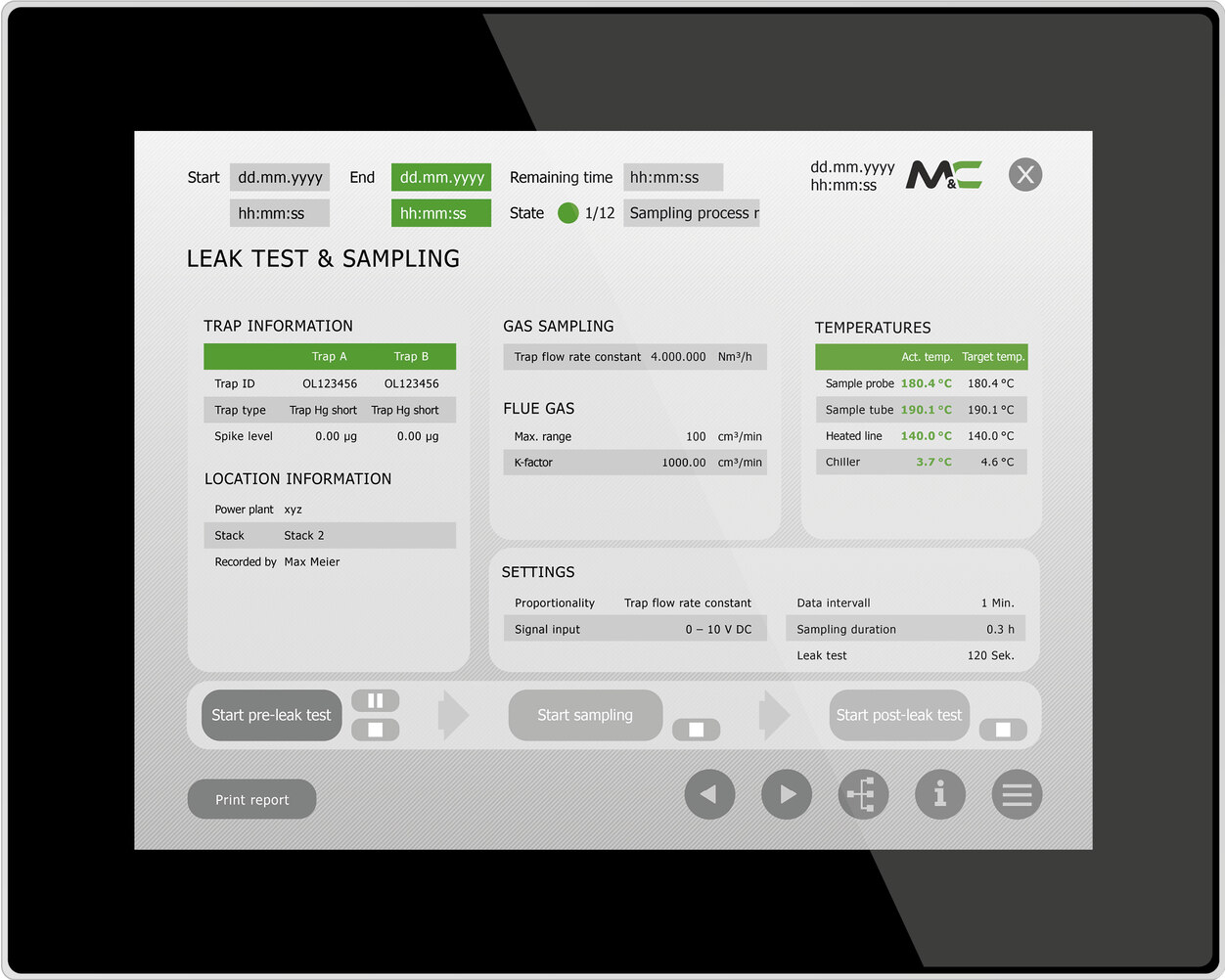

An Overview of the System

From Sampling to Analyzing – The Functional Principle.

The Individual Components of the PSS-STS

Our expert

Marco Meer

Produkt Manager

Phone: +49 2102 935-134

or contact him directly via our contact form.